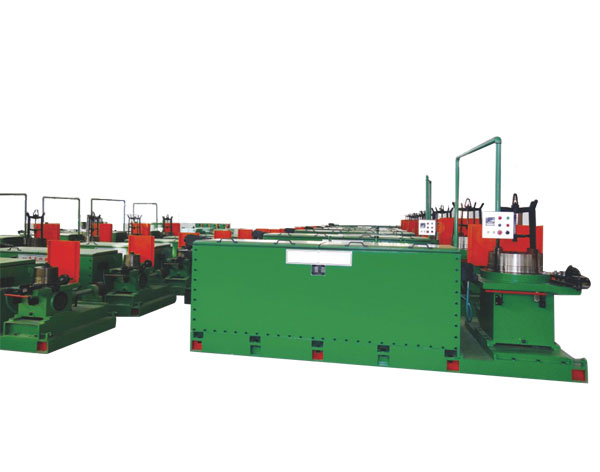

Heavy Wet Wire Drawing Machine

Description

Reducer of the machine applies 8-module herringbone gear and the gear or take-up box is 10-module with speed ratio of 1:1.High-speed gear shaft material is 40Cr with high-frequency quenching,the round tower according to the user needs to be divided into:common ZG55 cast steel,common ZG55 cast steel with high-frequency quenching,common ZG55 cast steel with tungsten carbide coating Transmission bearings all use famous brand products,tale-up transmission system coupling sub-installation,the axis of the stress distribution is reasonable. Reducer box,water tank,take-up box are installed in the same base for easy installation and lifting.Surface of the water tank is painted high grade and quality paint,inside and outside of the electrical cabinet both use plastic-spraying process. It is divided into common control and frequency control. The electrical compinents used in all Chinese or international famous brand products.

| Item | Unit | LZ9/1200-1000 | LZ9/1000-800 | LZ10/800 | LZ10/600(560) | LZ10/450(400) |

| Diameter of capstan | mm | 1200-1000 | 1100-800 | 800(700) | 600(560) | 450(400) |

| Drawing times | time | 9 | 9 | 10 | 10 | 10 |

| Maximum diameter of inlet wire | mm | φ14-φ10 | φ10-φ8 | φ9-φ6.5 | φ6.5-φ5.5 | φ4.5-φ2.5 |

| Minmum diameter of oulet wire | mm | φ5-φ3.5 | φ3.5-φ2.8 | φ2.8-φ2.0 | φ2.0-φ1.7 | φ1.4-φ0.8 |

| Drawing line speed | m/min | 300 | 360 | 480 | 720 | 840 |

| Inlet tensile strength | Mpa | ≤1300 | ≤1300 | ≤1300 | ≤1300 | ≤1300 |

| Total compression rate | % | 87.24 | 87.75 | 90.53 | 90.53 | 90.32 |

| Average compression rate | % | 20.45 | 20.8 | 21 | 21 | 20.83 |

| Motor power | Kw | 110-75 | 90-45 | 75-37 | 37-22 | 15-7.5 |